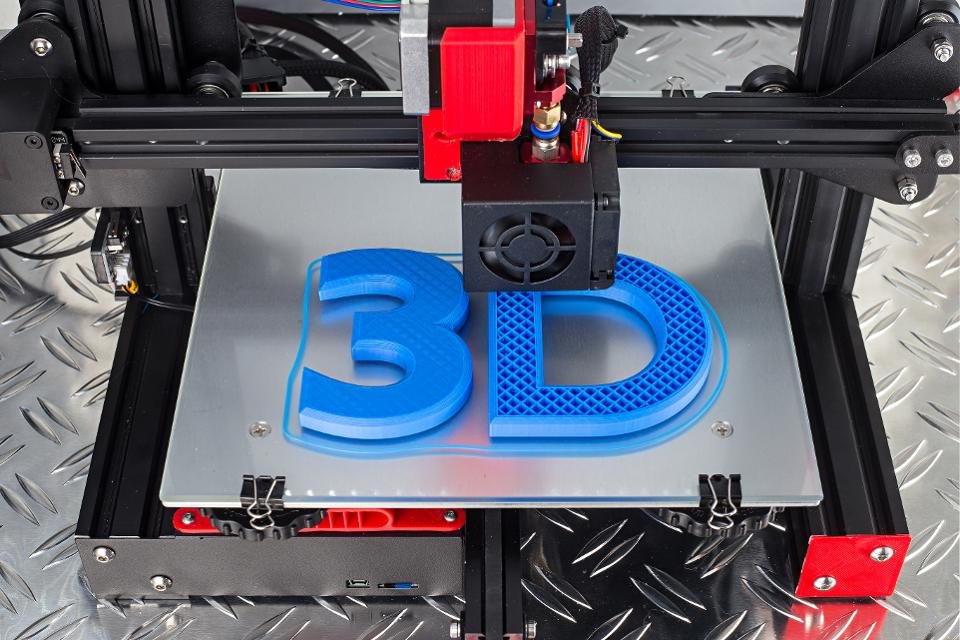

In today’s dynamic landscape of technological innovation, one disruptive force stands out in the realm of packaging: With those areas that are directly touched industries becoming increasingly efficient, leaner and customized 3D printing is clearly seen as a trend-setter. This breakthrough technology drastically changes classic ways of packaging design, manufacturing, and distribution providing a variety of solutions for industries ranging from healthcare to food preservation. In addition to additional sustainability issues and cost-efficiency, 3D printing of packaging has an immense impact on modern creativity and personalization.

Transforming Design Paradigms

First, 3D printing is capable of overcoming the constraints of traditional manufacturing techniques, by which it provides a new and much friendlier means of production. In contrast to conventional techniques, usually with laborious tooling and molding processes, 3D printing allows designers to communicate in a manner that is creative and dynamic too something unheard of. Sustainable and functional packaging solutions can be formed by applying digital design technologies and additive manufacturing methods and tailored to specific needs and applications with precision and efficiency. Such shift from mass production to mass customization give brands the ability to stand out in markets overwhelmed with similar offerings, and at the same time meet the changing needs of the ever demanding customers.

Optimizing Material Usage

In addition, the customizable feature of 3D printing in packing also makes material usage more efficient and minimizes wastage. On the contrary, with subtractive technology we get a significant percentage of scrap material, but additive manufacturing method adds the material layer by layer with the exact amount of needed material. This intrinsic efficiency not only alleviates burden on the environment but also gives businesses an edge in resource optimization and the reduction of their overhead costs through waste material reduction and transportation cost savings. Consequently, the capacity to implement recycled and biodegradable materials will add to the environmental factor of 3D-printed packaging solutions even more.

Facilitating Supply Chain Efficiency

In the area of packaging, the technology is the one to pay particular attention to, and 3D printing can be applied to facilitate and speed up the process. This technology replaces centralized production so that items can be manufactured as needed, and thus, it largely diminishes the need for government monitoring of distribution systems and inventory. In addition, transporting parts and raw materials within the vicinity of the target markets enables enterprises to cut short lead times and serve consumers’ needs in a quicker manner. It is not only this shortening of transportation distances that results in an increase in the efficiency of the processes, but also a decrease in carbon emissions associated with each distance travelled.

Enabling Personalization at Scale

The benefit that the 3D printing technology is best known for is the fact of it empowering brands to create personalized experiences for customers at the level of mass production. Furthering digital design capability and automation of production which makes it easier to meet the customized packaging preferences in a smooth fashion is one of the benefits of digitalization. Brands can achieve deeper consumer interaction and build more valuable emotional relationships with them via 3D printing, including product customization, logo embossing or smart ergonomics for example. Not only does it improve brand loyalty since this is a process that distinguishes the company from the competition but it allows it to specialize the marketing strategies and have a diverse range of products.

Pioneering New Frontiers

Recently, 3D printing is more and more influencing the designing and making of packaging apart from promoting trial and expansion of creativity. Whether it is the application of intelligent sensors and RFID tags or the advent of degradable and edible packaging materials, the frontier is as deep as one can imagine. As additive manufacturing technology stands at the frontier of the researchers and entrepreneurs, the next years of packaging are going to be determined by sustainability as a primary requirement, functionality, and consumer-oriented design.

Challenges and Opportunities Ahead

3D printing though opens an entirely new scope of packaging and offers its own challenges too. To deal with regulatory considerations, to protect intellectual property and the growth of production processes are only a few of the problems that have to be solved. Despite the fact that this is the case, the prospects for the development of more effective and efficient manufacturing processes are expected. Enterprises are adopting a 3D printing trend, taking up the power of it to overcome common manufacturing and material issues as an industry. The universe is open for a new era of innovation and sustainability in packaging.

Inculcating the finalized 3D printing inside the packaging sector is too much potential to change the whole but it would be revolutionary. Through the provision of more and more creative space for designers, this technology is going to change the essence of the packaging and as such perform the function beyond the limits of its making rules that used to be and foster the development of packaging created very specifically and adjusted to the requirements and tastes of its users. In addition, 3D printing helps reduce material wastage and side effects by fully utilizing materials, cutting down on waste and environmental impact as well as increasing efficiency and cost effectiveness of the production process.

Additionally, the participation of artificial intelligence in manufacturing shares also aims at mitigating the traditional supply chain bottlenecks through enhancing logistics and distribution channels, hence shortening the lead times and improving overall agility in response. The capability to print not only packaging materials but also their components on-demand, any time and place they are practically required, shall disrupt the paradigm of the way we manage our inventory and fulfil orders