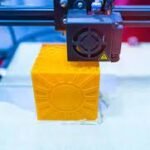

The industrial sector globally is investigating the adoption of new concepts and clean technologies to minimize environmental impact and stay relevant to consumers. They especially have the largest share in this industry since they are the components of packaging materials that lead to waste production and degrade the environment. In the near past 3D printing technology has been introduced as a beneficial tool to solve sustainable packaging problems. It is observed that the article discusses the multifaceted role of 3D printed packaging in bringing eco-friendliness and reduction of the environmental challenges.

Impact of the Ecological Disasters of Conventional Wrappings

Conventional packaging materials have been the primary choice of packaging firms for a long time: plastic, cardboard, and Styrofoam. On the other hand, these two materials usually have a lot of adverse impacts related to the environment. Case in point is that plastic packaging is one of the leading causes of global plastic pollution, an extensive problem where millions of tons of plastic reach the landfills and the oceans every year. Moreover, the manufacturing and getting rid of cardboard and paper cartons can lead to deforestation, habitual areas devastation and greenhouse gas emission. The ‘take-make-dispose’ matter which is proven to be the problem of traditional packaging systems accelerates resource depletion and environmental deterioration, thus making the sustainable alternatives a must.

Pros of 3D Printers Packaging for Being Green.

Material Efficiency: Contrary to traditional manufacturing methods that usually manufacture more wastes compared to the length of the production process, 3D printing guarantees excellent material efficiency. Generating the objects of a layer by layer structure as 3D printers do, largely reduces the generation of waste material hence the reduction of the raw material consumption. This technique gains its momentum in packaging where cutting down on materials is equally important as reducing the environmental impact.

Customization and Optimization: It is with 3D printing that you can create packaging, which is customized in order to fit specific products and consumer preferences. Through extrusion, 3D printing technology enables the production of packaging that meets dimensional accuracy, compressibility, and structural integrity requirements, thereby lowering the need for bulk packaging while enhancing space utilization at the same time.

Biodegradable and Recyclable Materials: An advanced trending point is the evolution of biodegradable and recyclable materials that are compatible with the 3D printing process, this improves the sustainability footprint of 3D printed packaging. Biopolymers, compostable plastics as well as recycled materials could also make environmentally-conserving packaging a practical and feasible alternative to traditional packaging through 3D printing methods. Such substances provide the plus of making the fossil fuels feedstock redundant and easy ways to handle them at the end of life such that they are friendly to the environment.

Localized Production: 3D printing disrupts the manufacturing processes in which goods are produced regionally near the places they are being consumed. This form of manufacturing ‘on demand’ or in conjunction with ‘on demand’ delivery minimizes the use of vehicles hence the carbon emissions related to distribution and logistics are eliminated. Due to 3D printing the provision of packaging materials and other products in closer proximity to the end-users, the supply chain is made more sustainable as it uses less energy and is less harmful to the environment.

Challenges and Considerations

While 3D printed packaging holds immense promise for sustainable practices, several challenges and considerations must be addressed to realize its full potential:While 3D printed packaging holds immense promise for sustainable practices, several challenges and considerations must be addressed to realize its full potential:

Material Selection: Designing appropriate materials of biodegradable, recycled, and non-poisonous kinds for 3D printing remains the central issue. Manufacturers are supposed to focus on the materials that satisfy the performance need, and at the same time should be a part of the sustainability objective.

Scalability and Cost: The fact that 3D printing cannot be scaled up for the production of packaging components by far is a fundamental drawback in terms of expenses, speed, and efficiency. Finance in technologies, infrastructures, and workforces are essential to remove the barriers and enable 3D printing to graduate from the small-scale application to the large-scale manufacturing industry.

Regulatory Compliance: The observance of regulatory norms concerning the eligibility of 3D printed food packaging for market acceptance is highly important, including the necessity of quality food safety and product labelling certifications, and chemical composition. Consensus of the actors on the market, the state authorities and the regulatory institutions is extremely important to elaborate the rules and norms which outline the eco-friendly packaging methods in a clear way.

Conclusion

From state to state of sustainable development, 3D printed packaging can be regarded as a potential solution in the industry with challenges connected to the sustainable use of raw materials. Through utilizing material efficiency, customization characteristics, as well as green materials, 3D printing packaging represents a road towards being environmentally friendly, reducing the amount of waste, preserving resources, and reducing impacts. On the other hand, the accomplishment of the maximum potential of 3D printed packaging needs the consistent efforts of the stakeholders from throughout the production chain who are capable of overcoming the barriers related to material and size restriction, regulation, and scalability. With the pay of a revolutionizing technology, collaboration with our competitor and the right investments the 3D printing packaging can be a good tool to respect eco friendly practices and condition a circular economy for packaging materials.