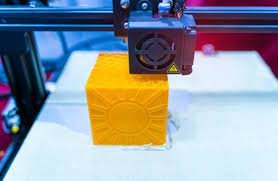

3d printing technology which is flexible and effective has brought changes in various industries like packaging. Thanks to the wide range of applications of 3D printed packaging, the industry operates in multiple fields, like food and beverages, healthcare and electronics. This article looks into the manifold usages of 3D printed packaging solutions and thus provides people with the innovation potential and practical applications of these products in various spheres of human endeavours.

Tailor – made Packaging for the Consumables Goods

Personalized Branding: The possibility in 3D printed packaging to create unique and vivid designs that are in sync with a brand is something that impresses companies. Besides having complex logos, personalized text, and graphics, 3D printing stands out as a way of individualizing packaging to suit specific audiences, and also increase brand recognition.

Product Differentiation: Being in a heavily competitive market and being unable to differentiate oneself from the competition is a recipe for failure. Three-dimensional printed packaging allows the product to meet the differentiation criteria as it has the ability to come up with unique shapes, textures and functionality. By using 3D technology for their product packaging, companies can not only ensure the product’s protection but also add a touch of consumer delight to their packaging.

Innovative solutions for the food and beverage industry are created.

Customized Food Packaging: In food industry 3D printed packaging is a kind of packaging way which is adapted to the special requirements of the different food product such as size, shape and material property. Therefore, individualization empowers companies to maximize packaging efficiency for freshness, portion control and convenience, as well as minimizes food waste.

Edible Packaging: As the editable materials and 3D printing technology evolve, the idea of edible packaging gradually come to the fore. Eco-friendly edible packaging stands as a potential substitute for conventional packaging materials and can be adopted to serve as a means to better connect consumers to the product and ultimately lower waste one packaging at a time.

Electronics and Consumer Goods

Protective Packaging for Electronics: Delicate items including electronic components are easily prone to excessive damage due to pack impact and rough handling. Therefore, they are specialty items necessitating carefully developed processes and packing solutions to prevent damage. Since 3D packaging can allow Padded, Shock Absorbing, Heat Protection and Travel safety of the products with less packaging waste at the same time.

Retail Display and Point-of-Sale Solutions: In retail spaces, 3D printers have new uses like to produce fashion icons or make all-purpose interactive stands and various size display. In addition, the third-party retailers can stoke the consumer’s interest about the 3D printed products, that will help drive the sales, since consumers love new achievements and uniqueness.

Promotional and Limited-Edition Packaging: The main difference between normal packaging and special packaging is that these special designs are produced with 3D printing technology which allows companies to make custom packaging designs for festivals, seasons and limited-edition marketing purposes. One example is that the amenities and 3D printing tech provide can transform less interesting package variants into beauty with its fine textures, interative details and combinations, which looks so amazing to the visitors and makes sales. There will be an additional reduced-: – letters edition collection that will not only represent little important items but will also help the brand to differentiate from other and will draw positive response from consumers by creating a memorable and mild hearted experience. In addition, the brand can create memorable experiences, by incorporating 3D printed promotional packaging, that support evoke the brand’s values and convincing the targeted audiences to positively perceive the brand. Moreover, the brand will maintain a good image in the market.

Space-saving and Nesting Designs: 3D printing enables the production of the packaging that having a taping or collapsible format to increase pack reconfiguration for warehousing and shipping and for showcase during retail sales. For example, that manufacturers can make wrappings that can be put together in sequence or compressed if it is unfilled which in return will decrease the volume of packaging. This also reduces the cost of the shipping and the carbon printed due to transportation. The warehouses really fit the context of online shop and the retail development where the space utilization is absolutely of great need for the resource constraints. Besides that, the development of the manufacture of the boxes can not only give the chance to the introduction of the eco-friendly practices by decreasing the amount of wastage of the packaging that is produced and also ensuring the use of recyclable or reusable packaging materials.

Conclusion

The multi-faceted utilities of 3D printing in packaging solutions create the vision of technology application with plenty of upsides in many different industries. Beside the unique branding and novel packaging options for edible products, 3D printed medical devices and displays in retails bring endless creative and recyclable packages solutions. As the technology progresses and materials become more advanced, during the coming years the company would grow due to being able to satisfy consumer demands for customization, sustainability, and innovation in the design of packaging.